History of Zinc white:

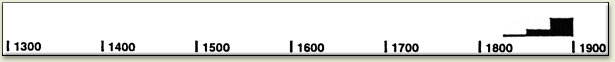

Zinc has been known as a mineral since antiquity when it was melted with copper to form brass. It was also known then, as it is today, as a medicinal ointment. Sources differ on who first isolated the element. Harley and Wehlte claim it was Henkel in 1421 who first produced metallic zinc. Gettens and Stout maintain it was the German chemist, Margraaf in 1746. Historians agree, however, that in 1782, zinc oxide was suggested as a white pigment. Guyton de Morveau at L'Académie de Dijon, France, reported on white pigments and the raw materials which might serve as white pigments, including zinc oxide in that year. He suggested zinc oxide as a substitute for white lead. Metallic zinc had originally come from China and the East Indies. When zinc ore was found in Europe, large-scale production of the extracted metallic zinc began. In 1794 and 1796 patents were issued for the manufacture of zinc oxide to the English colormaker John Atkinson of Harrington Near Liverpool.

Zinc white was accepted as a watercolor by 1834 but it was some years later before its difficulties in oil were overcome. In 1834, Winsor and Newton, Limited, of London, introduced a particularly dense form of zinc oxide which was sold as Chinese white. It was different from former zinc white in that the zinc was heated at much higher temperatures than the late eighteenth century variety. The name 'Chinese white' is said to have come from the oriental porcelain that was very popular in Europe in the eighteenth and nineteenth centuries. George H. Backhoffner of London disputed Winsor and Newton's claim of their superior white watercolor in his book Chemistry as Applied to the Fine Arts, London, 1837. Backhoffner recommended Flemish white as superior (white lead). Winsor and Newton believed that although scientists would ignore Backhoffner, artists would not use the Chinese white because Backhoffner lectured widely in the Art Academies and his opinion would be well known to them. In 1837, Winsor and Newton published a response to Backhoffner in Remarks on White Pigments used by WaterColour Painters and distributed copies to the artists. They were successful in convincing artists of the superiority of Chinese white because the name is still synonymous today for all zinc white in watercolor.

By 1844, a better zinc white for oil was developed by LeClaire in Paris. He ground the zinc oxide with poppy oil that had been made fast drying by boiling it with pyrolusite (MnO2). In 1845, he was producing the oil paint on a large scale. By 1850, zinc white was being manufactured throughout Europe.

Zinc white was still a slow drying white requiring twenty-three parts of oil to one hundred parts of pigment whereas lead white requires fifteen parts of oil. Zinc is essentially permanent in sunlight although the yellowing in oil affects its brightness. It had advantages over white lead because it was not blackened by sulphur-bearing air or other pigments containing sulphur, as lead is. It is non-toxic and more economical than white lead.

It is neiter as opaque nor heavy as lead white and it takes much longer to dry. Because zinc white is so "clean" it is very valuable for making tints with other colors. Tints made with zinc white show every nuance of a color's undertones to a degree greater than tints made with other whites, and the artist has time to complete his work before the paint dries. Despite its many advantages over lead white, zinc white oil color also has a drawback; it makes a rather brittle dry paint film when used unmixed with other colors. Zinc whites' lack of pliancy can cause cracks in paintings after only a few years if this color is used straight up to excess. For example, during the late 1890's and very early 1900's some artists used zinc white as a ground for their oil paintings. They wanted to utilize the brilliance of this color, but did not realize its long term disadvantage. After a period of years, all of these paintings developed cracks where older works painted on more traditional grounds remained free from cracks.It is perfectly safe to use in moderate amounts for normal color mixing and for painting. Because it is relatively slow drying, zinc white is also useful for highlighting, as it will not dry faster than the color it was painted over. However, it would be a poor choice for painting a Winterscape or similar paintings having large expanses of white, because zinc white dries to a brittle film that would crack.

When was Zinc white used?

| Discovery | Used until |

|---|---|

| 1834 | continues in use |

Use of Zinc white among paintings in the SchackGallery, Munich:

Source: Kühn