How Smalt is made:

| Artificial variety of pigment | The cobalt ore was roasted and the cobalt oxide obtained was melted together with quartz and potash or added to molten glass. When poured into cold water, the blue melt disintegrated into particles, and there were ground in water mills and elutriated. Several grades of smalt were made according to cobalt content and grain size. In the complex ores in Saxony, as they were first roasted, much of the arsenic was volatilized. The oxides of cobalt, nickel and iron were then melted together with siliceous sand, and the resulting product called Zaffre or Zaffera were, in part, sold to potters and glassmakers. Another modern recipe is heating of quartz, potassium carbonate and small amount of cobalt(II)-chloride to 1150°C and inserting the still hot product into cold water. The disintegrated glass is then homogenized in a mortar. The principal source of cobalt used in the preparation of smalt in Europe during the Middle Ages appearing to be the mineral smaltite, one of the skutterudite mineral series. In the seventeenth and eighteenth centuries other associated cobalt minerals were probably used as well (erythrite and cobaltite). |

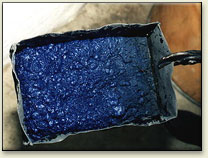

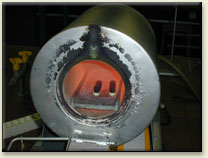

Illustration of the process:

Making smalt at Kremer Pigments

|

|

|

|

|

|

|

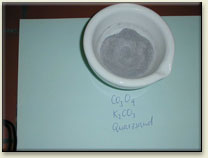

Making smalt in the student laboratory

|

|

|

|

|

|

|

|

|

|

|

|

|

The ground pigment:

Pile of ground Smalt

(intro) - Azurite - Cerulean Blue - Cobalt blue - Egyptian blue - Prussian blue - Smalt - Ultramarine