How Lead-tin yellow is made:

| Artificial variety of pigment | Lead-tin yellow (type II) is produced by fusing lead, tin, and quartz compounds at about 800° C, yielding a yellow lead glass pigment that is ground and screened through a fine mesh. |

| In the lab | |

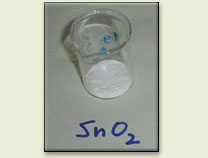

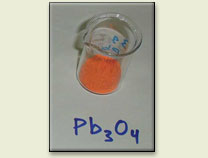

| Materials needed: | PbO or PbO2 or Pb3O4 (minium) and SnO2 |

| Safety (MSDSs): | Tin(IV) oxide, lead(II) oxide, lead(IV) oxide, (at Fisher Scientific) |

| Method: | Mixture of three parts lead oxide(PbO, PbO2, or minium) and one part tin oxide(SnO2) is heated at temperatures between 650 and 800°C. Lower temperatures yield a more orange color, higher temperatures yield more lemon-hued colors. Some types of lead-tin yellow are prepared in molten glass. |

Illustration of the process:

Making lead-tin yellow in the laboratory

|

|

|

|

|

|

|

|

|

|

| The reaction mixture prior to heating |

|

|

The ground pigment:

Pile of ground Lead-tin yellow

Other yellows

(intro) - Cadmium yellow/red - Chrome yellow - Cobalt yellow - Indian yellow - Lead-tin yellow - Lemon yellow - Naples yellow - Orpiment - Yellow ochre

(intro) - Cadmium yellow/red - Chrome yellow - Cobalt yellow - Indian yellow - Lead-tin yellow - Lemon yellow - Naples yellow - Orpiment - Yellow ochre