How Viridian is made:

| Artificial variety of pigment | Calcining a mixture of of boric acid and potassium bichromate and washing the material thus formed. |

| 19th century recipe | Mix 3 parts of boracic acid and 1 part of bichromate of potassa, heat to about redness. Oxygen gas and water are given off. The resulting salt when thrown into water is decomposed. The precipitate is collected and washed. This is a remarkably fine color, solid and brilliant even by artificial light. |

| In the lab | |

| Materials needed: | Potassium dichromate (K2Cr2O7), boric acid (H3BO3) |

| Safety (MSDSs): | boric acid, potassium dichromate (at Fisher Scientific) |

| Method: | 5 g boric acid and 2,5 g potassium dichromate are mixed together and heated to 500°C for 6 hours. The cooled mixture is then pulverised, added to cold water and stirred until bright green colour is visible. The pigment is then filtered off and dried. |

Illustration of the process:

Making viridian in the laboratory:

|

|

|

| Boric acid and potassium bichromate are being homogenized | The reaction mixture prior to heating | |

|

|

||

|

|

|

| The mixture at the start of the heating stage | After 6 hours at 500°C | |

|

|

||

|

|

|

| The cooled chromium(III) oxide prior to reaction with water. The color is dull green | The hydratation of chromium(III) oxide brings about the characteristic fiery green color of viridian. | |

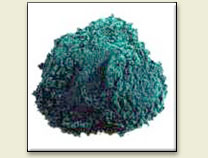

The ground pigment:

Pile of ground Viridian

Other greens

(intro) - Cobalt green - Copper resinate - Emerald green - Green earth - Malachite - Verdigris - Viridian

(intro) - Cobalt green - Copper resinate - Emerald green - Green earth - Malachite - Verdigris - Viridian